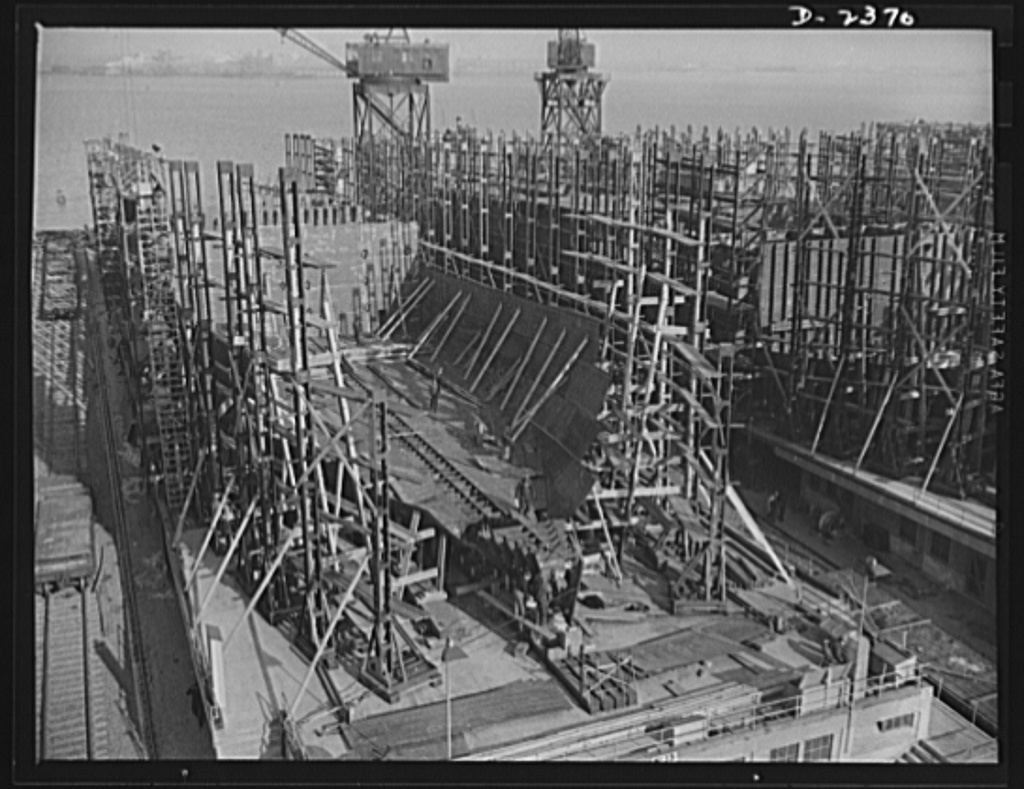

The mechanisms of residual stress formation and distortion are explained in connection with stiffened panel fabrication, with an emphasis on weld induced buckling of thin panels. Friction stir welding as one of the key methods of solid state welding as applied to aluminum alloys is also addressed. Various fusion welding methods, MMAW, GMAW, SAW, Electroslag welding and Electrogas welding and single side welding are explained in detail. Welding power source characteristics, metal transfer mechanisms, welding parameters and their effects on the fusion zone, weld deposit, and weld bead profile are discussed in detail. The concept of line heating for plate bending is introduced. Various methods of steel material preparation are discussed, and plate cutting and forming of plates and sections are explained. With regard to construction materials, the book discusses steel, aluminum alloys and fiber reinforced composites.

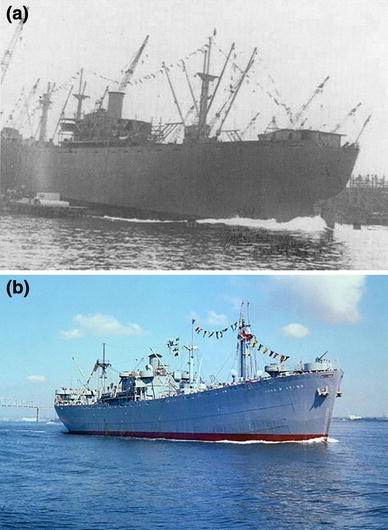

The midship sections of various ship types are introduced, together with structural continuity and alignment in ship structures. It presents in detail double bottom construction, wing tanks & duct keels, fore & aft end structures, etc., together with necessary illustrations.

along with structural subassemblies like floors, bulkheads, inner bottom, decks and shells.

The book covers structural arrangement with longitudinal and transverse framing systems based on the service load, and explains basic structural elements like hatch side girders, hatch end beams, stringers, etc. The contents of the book are logically organized and divided into twenty-one chapters. This book addresses various aspects of ship construction, from ship types and construction materials, to welding technologies and accuracy control.

0 kommentar(er)

0 kommentar(er)